So, you're thinking about owning a private plane. It’s an incredible experience, but the sticker price is just the beginning of the story. A good rule of thumb? Expect to spend 5% to 10% of the aircraft's market value every year on maintenance.

That means a $2 million aircraft isn't a one-time purchase; it's a commitment that could easily demand $100,000 to $200,000 in yearly upkeep. This isn't just about fixing things—it's about a continuous cycle of inspections, preventative care, and major overhauls. Getting a firm handle on these expenses is what separates a successful owner from one who's constantly caught off guard.

Breaking Down Private Plane Maintenance Costs

Managing aircraft maintenance isn't about waiting for something to break. It's a proactive, federally regulated program designed to ensure safety and preserve the value of your asset. To build a realistic budget, you first need to understand that all maintenance spending falls into two distinct categories.

Think of it like owning a classic car. Some expenses, like insurance and garage space, you pay whether you drive it or not. Other costs, like oil changes, new tires, and engine work, depend entirely on how much time you spend on the road. Aviation finance works the same way, but with much higher stakes.

The Two Pillars of Maintenance Expenses

Every single dollar you put into your aircraft's upkeep will land in one of two buckets. Understanding this distinction is the absolute first step to avoiding the kind of financial surprises that can ground an unprepared owner.

- Fixed Costs: These are your predictable, non-negotiable expenses. You pay them just for the privilege of ownership, whether you fly 10 hours a year or 100. They form the baseline of your annual budget.

- Variable Costs: These expenses are directly tied to how much you use the plane. The more hours you log in the sky, the more you'll spend here, as every flight puts wear and tear on the machine.

What Are Fixed Costs?

Fixed costs are the foundation of your aviation budget. They show up like clockwork on your calendar, giving you a solid, predictable financial base. The biggest line item here is almost always insurance. It’s a complex topic, and you can get a better sense of what to expect by reading our guide on the cost of airplane insurance.

Other major fixed costs include hangar fees—which can run from a few thousand a year to over $100,000 annually in a major city—and subscriptions for things like navigation and avionics databases.

A common mistake new owners make is underestimating fixed costs. Hangar space, insurance, and database subscriptions can easily add up to tens of thousands of dollars before the plane even leaves the ground for its first flight of the year.

What Are Variable Costs?

Variable costs, on the other hand, are all about usage. Fuel is the most obvious one, but from a maintenance standpoint, this category includes everything driven by flight hours. We're talking about mandated 100-hour inspections for aircraft used in commercial operations, as well as replacing components that have a defined lifespan, known in the industry as Time Between Overhaul (TBO).

Every hour you fly ticks the clock closer to these major, five- or six-figure expenses. This is why a dedicated reserve fund for overhauls isn't just a smart idea—it's an absolute necessity for anyone serious about long-term aircraft ownership.

Understanding Your Aircraft Budget: Fixed vs. Variable Costs

When you own an airplane, you quickly learn to think like a bookkeeper. Every dollar you spend on maintenance falls into one of two buckets: costs you pay no matter what, and costs that rack up every time you push the throttle forward. Getting a handle on this split between fixed and variable expenses is the single most important step toward a predictable, stress-free ownership experience.

Think of it like owning a high-performance car. Your insurance bill and the fee for your climate-controlled garage are fixed costs—you’re on the hook for them even if the car never leaves its parking spot. An aircraft is no different; it accumulates some hefty bills just by existing. These predictable, recurring charges are the bedrock of your annual budget.

On the other hand, the more you drive that car, the more you'll spend on gas, tires, and oil changes. These are your variable costs, tied directly to how much you use it. For an aircraft, this is everything from routine 100-hour inspections to the slow, expensive wear and tear on a multi-million dollar turbine engine.

The Foundation of Your Budget: Fixed Costs

Your fixed costs are the expenses you can count on, year in and year out. They create a financial baseline that makes long-term budget planning possible. These aren't just about parts and labor; they’re about keeping the aircraft protected, insured, and ready to fly.

These predictable costs almost always include:

- Hangar or Tie-Down Fees: Leaving a multi-million dollar asset out in the sun and rain simply isn't an option. Securing a proper hangar, especially near a major city, can easily run over $100,000 annually for a larger jet.

- Insurance Premiums: This is a huge fixed cost. The final number depends on the plane’s value, your pilot experience, and its intended use.

- Avionics and Navigation Database Subscriptions: A modern glass cockpit is powered by software, and that software needs constant updates. These annual subscriptions often add up to thousands of dollars.

- Enrollment in Maintenance Programs: Many owners choose to enroll their engines or airframes in programs that turn a massive, unpredictable overhaul bill into a predictable monthly or hourly payment.

These programs are essentially a high-end service plan for your aircraft. You pay a steady amount to smooth out the financial shock of a future engine overhaul, which makes budgeting infinitely easier. The logic here is the same as we've discussed for other high-value assets, like in our guide to creating a fleet vehicle maintenance checklist, where scheduled planning prevents crippling surprise costs.

The "Pay-As-You-Fly" Model: Variable Costs

Variable costs are where your flying habits hit your wallet directly. The more you're in the air, the faster these usage-based expenses will come due. This part of your budget is dynamic and needs constant attention because it’s a direct reflection of how much you're actually using the plane.

Understanding the link between flight hours and variable costs is absolutely critical. An owner flying 300 hours a year will face major inspections and overhauls far sooner than someone who only puts 50 hours on the Hobbs meter.

The biggest variable costs are driven by flight hours and cycles (one takeoff and one landing). A clear way to visualize this is by breaking down the common expenses.

Comparing Fixed vs Variable Maintenance Expenses

This table shows how different costs fall into either the recurring (fixed) or usage-based (variable) category.

| Expense Type | Fixed Cost Examples (Recurring) | Variable Cost Examples (Usage-Based) |

|---|---|---|

| Housing & Readiness | Hangar rent, insurance premiums, database subscriptions | Landing fees, repositioning flights |

| Scheduled Inspections | N/A (Inspections are triggered by usage or calendar) | Annual/100-Hour inspections, phase checks |

| Component Wear | Fixed-cost maintenance program fees | Engine overhaul reserves, propeller overhauls, tire replacement |

| Unscheduled Events | N/A | Bird strike repairs, unexpected component failures |

For many new owners, the sheer scale of these variable costs can be eye-watering. For instance, private jet maintenance costs frequently fall in the $500,000 to over $1 million range each year, as detailed in this breakdown of private jet maintenance expenses on StratosJets.com. This covers everything from simple service to major component replacements.

This is exactly why a proactive savings plan—often called a maintenance reserve—is non-negotiable. By setting aside a specific amount of money for every hour you fly, you build up a dedicated fund to cover those massive, inevitable bills when they finally come due.

Understanding Your Scheduled Maintenance Program

Think of scheduled maintenance as the very pulse of your aircraft. It’s the predictable, calendar-driven side of ownership that governs both your budget and your safety. Unlike your car, where you might push an oil change a few hundred miles, an aircraft's maintenance program is a non-negotiable, federally regulated roadmap. It's how you stay ahead of problems.

This isn't just about ticking boxes; it's a series of mandatory health check-ups for your plane. Each inspection is designed to find small issues before they snowball into catastrophic failures. Following this schedule religiously is the single best way to keep your aircraft airworthy, protect its value, and avoid the kind of eye-watering repair bills that can ground an owner for good.

The Rhythm of Inspections: Annual vs. Phase Checks

Not all inspections are built the same. The frequency, complexity, and cost are tied directly to the kind of aircraft you fly. A simple piston single follows a very different beat than a high-performance corporate jet.

For most piston-engine aircraft, the cornerstone is the Annual Inspection. Just like it sounds, this is a top-to-bottom, exhaustive examination that has to be done every 12 calendar months. A mechanic will go through the entire aircraft with a fine-tooth comb, checking everything from engine compression to the flight control cables, hunting for any signs of wear, corrosion, or damage. It's intense.

Once you move into more complex aircraft like turboprops and jets, the schedule often shifts to a Phase Check program. Instead of one massive, time-consuming annual event, the inspection is broken down into smaller, more frequent "phases." This smart approach minimizes downtime, which is absolutely critical for anyone operating a busy aircraft. For those managing several planes, this strategy is a key part of effective fleet management, a topic we dive into deeper in our guide to fleet management best practices.

Demystifying Time Between Overhaul (TBO)

While inspections cover the routine check-ups, the concept of Time Between Overhaul (TBO) deals with the single biggest planned expense you'll likely ever face. TBO is the manufacturer's recommended lifespan for your most critical components—namely the engine and propeller—measured in flight hours or calendar years.

Imagine your engine came with a built-in countdown timer set at the factory. Every hour you fly clicks that timer down. When it hits zero, it’s time for a complete overhaul, which means tearing it down and rebuilding it to factory-new specifications.

This isn't a friendly suggestion. For commercial operators, it's a hard rule. For private owners, it’s a critical benchmark for safety and resale value. An engine overhaul for a piston aircraft can easily run $20,000 to $50,000, and for a private jet turbine engine? You could be looking at over $1 million. This is precisely why a dedicated maintenance reserve fund isn't just a good idea—it's essential.

What Mechanics Are Actually Looking For

During these scheduled events, mechanics are doing a lot more than just kicking the tires. They are methodically working through a highly detailed checklist specific to your aircraft's make and model, often containing hundreds of items.

Here’s a glimpse of what’s happening:

- System Diagnostics: They’ll run tests on avionics, hydraulics, and electrical systems to make sure everything is performing exactly as it should.

- Component Lubrication: Every moving part, from the landing gear joints to the flap actuator, gets lubricated to prevent friction and premature wear.

- Fluid Analysis: Small samples of engine oil and hydraulic fluid are sent to a lab. Technicians analyze them for microscopic metal particles, which can be an early warning sign of internal engine wear long before you'd notice a problem.

- Structural Inspection: They examine the airframe for hidden corrosion or tiny stress fractures, paying special attention to areas known to be weak spots on that particular model.

The entire philosophy is proactive, not reactive. This disciplined approach to upkeep isn't unique to aviation; it's a core principle for managing any high-value asset. For another perspective on this kind of systematic planning, you can find similar strategies in this Ultimate Commercial Building Maintenance Checklist. By systematically addressing every component on a set schedule, you can plan for major costs and ensure your aircraft remains safe and reliable for years to come.

Budgeting for the Big Stuff: Major Overhauls and Replacements

If routine inspections are the steady, predictable heartbeat of your maintenance plan, major overhauls are the financial earthquakes. We’re not talking about fixing something that’s broken; we're talking about replacing critical, multi-million-dollar components simply because their factory-set lifespan is up. This is where you absolutely must shift from a reactive mindset to a long-term financial strategy.

The numbers here can be breathtaking. A complete engine overhaul on a simple piston plane can easily run $20,000 to $50,000. For a midsize jet, you could be looking at a bill well over $1 million for a single engine. That’s why I always tell new owners: the purchase price is just the entry ticket. The real test is your ability to plan for these massive, unavoidable expenses years down the road.

The Ticking Clock on Life-Limited Parts

At the core of this planning is the concept of life-limited parts. Think of your engines, propellers, and landing gear as having a built-in, non-negotiable expiration date set by the manufacturer. This limit isn't just a suggestion; it’s measured in flight hours, cycles (one takeoff and one landing), or sometimes, just calendar years.

Unlike a part in your car that you replace when it fails, these aircraft components must be overhauled or replaced the moment they hit their limit, even if they seem to be working perfectly. Ignoring this isn't just a bad idea—it’s illegal, violating federal regulations and jeopardizing the safety of everyone on board.

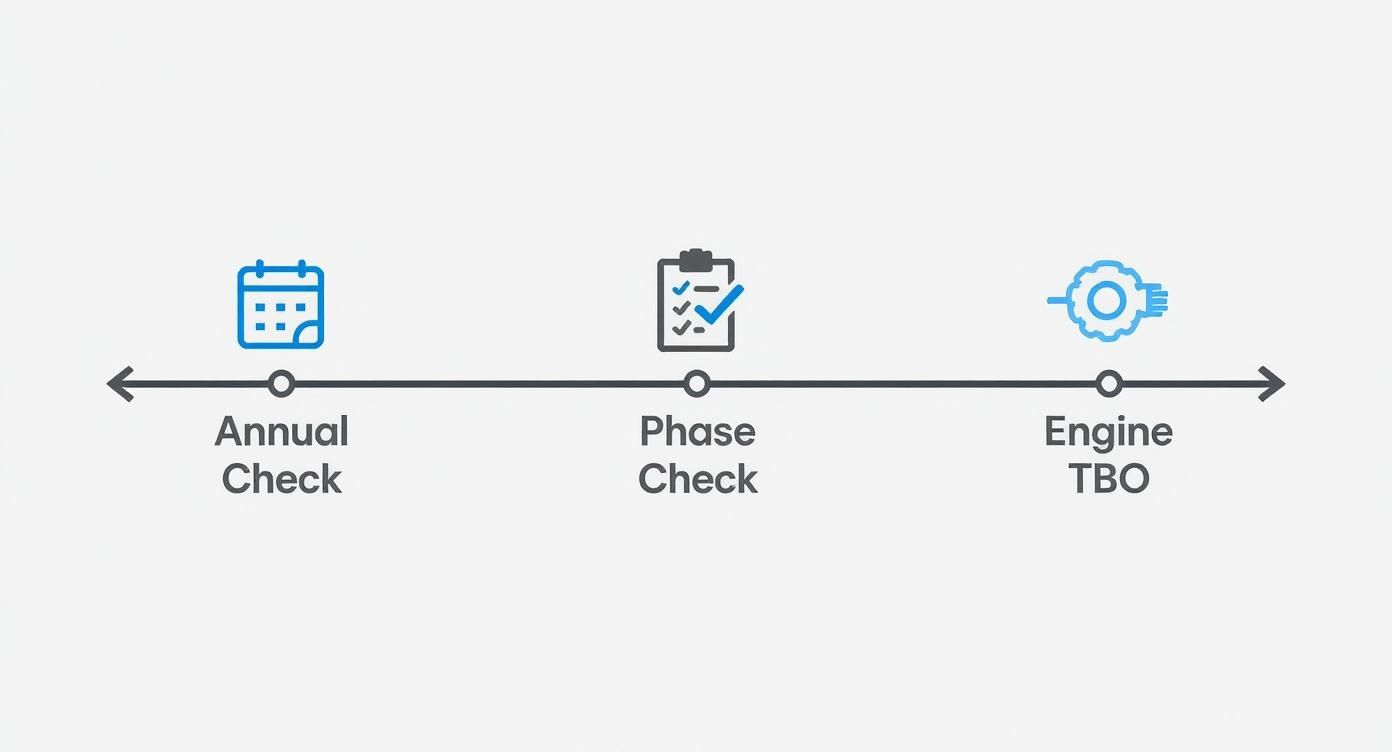

The graphic below puts this into perspective, showing how these major Time Between Overhaul (TBO) events stack up against more frequent checks.

As you can see, while annual inspections are a constant, the engine TBO is that giant, looming expense that you have to start saving for from day one.

Building Your Maintenance Reserve Fund: A Non-Negotiable

A dedicated maintenance reserve fund is the only sane way to handle these costs. It’s a simple but incredibly powerful practice: for every hour you fly, you set aside a specific amount of money into a separate account. This account is sacred—it's exclusively for future overhauls. Doing this transforms a crippling lump-sum payment into a manageable, predictable operating cost.

Let’s look at some real-world numbers:

- Light Piston Aircraft (like a Cirrus SR22): The engine TBO is often around 2,000 hours. If a new overhaul costs $40,000, you need to be saving $20 for every single hour the plane is in the air.

- Midsize Jet (like a Cessna Citation XLS+): The engine overhaul might cost $1.2 million and comes due at 5,000 hours. That breaks down to a staggering $240 per hour, per engine, just for the overhaul fund.

I can’t stress this enough: failing to fund a maintenance reserve is one of the biggest financial blunders an owner can make. When that million-dollar invoice arrives, having no reserve can force a distressed sale of the aircraft, often at a huge loss.

The Hidden Cost of Mandatory Tech Upgrades

It’s not just the mechanical parts. You also have to plan for mandatory technology upgrades. Aviation authorities like the FAA periodically require new avionics to improve safety and air traffic control. A perfect example was the recent ADS-B mandate, which forced thousands of owners to spend anywhere from $5,000 to over $20,000 per aircraft to install new transponders.

These upgrades aren't optional. Without them, your aircraft can be legally grounded or barred from flying in huge swaths of controlled airspace. Smart financial planning means keeping an ear to the ground for upcoming regulatory changes and budgeting for the required tech years before the deadline. It’s all part of protecting the total value of your asset. You can think about it in a similar way to insurance; to get a clearer picture of this principle, it's helpful to understand what is replacement cost coverage and apply that forward-thinking mindset to your aircraft’s future.

Planning for Unscheduled Repairs and Costly Downtime

Even the most meticulously planned budget has its kryptonite: unscheduled maintenance. These are the sudden, unavoidable storms of aircraft ownership. You can set your watch by an annual inspection, but you can’t pencil in a bird strike on final approach, a cracked windshield you spot during a walk-around, or a key piece of avionics going dark mid-flight.

These surprises are an inescapable part of private plane maintenance costs, and they hit you in two ways. First, there's the direct, out-of-pocket cost of the repair itself—anything from a few thousand dollars for a new tire to a six-figure bill for a major component failure. But the second cost, downtime, is often the most painful.

The True Cost of a Grounded Aircraft

When your plane is grounded, it's more than just an inconvenience; it's a non-performing asset bleeding money. Every hour it sits in the hangar waiting for a part or a mechanic's attention, you're still paying for hangar space, insurance, and financing.

The real-world impact depends entirely on how you use the aircraft:

- For a Business: A grounded jet means canceled executive meetings, broken supply chains, and very real lost revenue. The cost of chartering a replacement at the last minute can be staggering.

- For a Private Owner: This is the stuff of ruined vacations and logistical nightmares. Suddenly, your multi-million-dollar key to freedom is a very expensive paperweight.

- For a Flight School: An aircraft on the ground is an empty classroom. It’s a direct hit to your bottom line, causing lost training revenue and throwing student schedules into chaos.

This is exactly why smart owners plan for the unexpected. For any business-use aircraft, this kind of thinking should be part of a broader business continuity plan checklist, ensuring operations don't grind to a halt when a critical asset is out of commission.

Common Unscheduled Repair Scenarios

You can't predict when something will break, but you can certainly anticipate what might break. Knowing the common culprits and their price tags helps turn a potential crisis into a manageable problem.

Here are a few classic examples you should be ready for:

- Tire Replacement: A blown tire from a hard landing or runway debris can easily run $1,500 to $5,000 once you factor in labor.

- Bird Strike Damage: This is a total wild card. Depending on where the bird hits, you could be looking at a minor cosmetic fix or a major structural repair costing $20,000 or more.

- Avionics Failure: That one black screen in your glass cockpit? Fixing it could cost anywhere from $5,000 to $25,000, depending on the unit that failed.

- Windshield Damage: A crack from an impact or even a de-icing system malfunction can trigger a replacement that costs upwards of $50,000 on a jet.

An established relationship with a trusted and responsive maintenance facility is your best defense against prolonged downtime. A mechanic who knows your aircraft and can prioritize your repair can save you days or even weeks on the ground.

When you add it all up, these ongoing expenses are significant. As a general rule of thumb, expect your total annual maintenance costs to fall between 5% to 10% of the aircraft's current market value. This is a solid benchmark for budgeting. For a jet valued at $5 million, that means setting aside $250,000 to $500,000 each year to cover both the planned inspections and the inevitable surprises. By planning for the unexpected, you can absorb these events without derailing your entire operation.

Smart Ways to Keep Your Maintenance Budget in Check

Let's face it, owning an airplane means spending money on maintenance. There's no way around it. But you don't have to just sit back and watch the bills pile up. By taking charge of your private plane maintenance costs, you can save tens of thousands of dollars a year without ever cutting a single corner on safety. It's all about shifting your mindset from "fix it when it breaks" to thinking ahead.

The single best thing you can do is get ahead of problems. This is proactive maintenance in a nutshell. When you spot a minor issue—a tiny oil leak, a light that flickers, a new vibration—you jump on it immediately. Small problems have a nasty habit of snowballing into catastrophic failures, turning a simple fix into an engine overhaul that grounds your plane and empties your bank account.

Should You Sign Up for a Maintenance Program?

For the really big-ticket items like engines and airframes, a dedicated maintenance program can be a financial lifesaver. Think of it like a high-end service plan for your plane. You pay a set amount, usually based on every hour you fly, and that money goes into a fund to cover future inspections and overhauls.

Yes, these programs add a predictable cost to your monthly budget. But they completely remove the gut-punch of a surprise seven-figure engine bill. It smooths out your cash flow and makes financial planning a whole lot easier.

Signing up for an hourly maintenance program turns a huge, unpredictable financial risk into a stable, manageable operating expense. It's one of the most powerful budgeting tools an aircraft owner has.

Finding the Right Maintenance Partner

Who you trust to work on your plane is one of the biggest financial decisions you'll make. A cheap quote up front often doesn't mean the best value in the long run. A top-notch shop with technicians who live and breathe your specific aircraft model will find and fix problems faster, which saves you a bundle on labor costs.

When you're vetting a maintenance shop, here’s what to look for:

- Model-Specific Experience: Do they see a lot of planes like yours? A mechanic who knows your model inside and out will spot common issues a mile away.

- Clear Communication: A good shop gives you detailed estimates and keeps you in the loop. No one likes surprise charges on the final invoice.

- Solid Reputation: Don't be afraid to ask for references from other owners with the same type of aircraft. Their experience will tell you everything you need to know.

Your Logbooks Are a Financial Tool

Keeping meticulous records isn't just about satisfying the FAA—it’s money in the bank. When your logbooks are clean, organized, and detailed, annual inspections go much smoother. The mechanic can quickly see the entire history of every part, which means fewer hours on the clock for you to pay for.

Beyond that, a perfect set of logbooks dramatically increases your aircraft's resale value. A buyer will gladly pay a premium for a plane with a transparent, well-documented history. It gives them confidence that the aircraft has been cared for properly. Protecting the aircraft's exterior is also part of the long-term plan; for example, you can learn more about what graphene coatings are and how they help reduce wear and tear. Remember, how you fly matters, too. Smooth, steady flying puts far less strain on the engine and airframe than aggressive maneuvers, helping your components last longer and pushing those expensive replacements further down the road.

Answering Your Top Maintenance Cost Questions

When you start digging into the realities of aircraft ownership, the same questions always seem to pop up. Let's tackle some of the most common ones I hear from clients, both new and experienced.

Is Owning a Jet Cheaper Than Chartering?

For the vast majority of flyers, the answer is a firm no. Chartering is a "pay-as-you-go" model. You use the plane, you pay for the trip, and that's it. You completely sidestep the relentless fixed costs that come with ownership—things like hangar space, insurance, and paying a crew.

Ownership really only starts to make financial sense when you're flying a lot. The tipping point is usually somewhere around 200 to 300 flight hours per year. Anything less than that, and you’re spreading those massive fixed costs over too few hours, making on-demand charter the much smarter, more economical choice.

How Much Should I Budget for an Engine Overhaul Reserve?

This is one of the most important—and most often ignored—parts of budgeting. The math is simple: take the estimated cost of a full overhaul and divide it by the engine's Time Between Overhaul (TBO) in hours. This gives you the amount you absolutely must set aside for every single hour you fly.

- Piston Aircraft Example: Let's say you're looking at a $40,000 overhaul for an engine with a 2,000-hour TBO. You need to be putting away $20 for every flight hour.

- Light Jet Example: A pair of jet engines might cost $500,000 each to overhaul at a 4,000-hour TBO. That means you have to save $125 per flight hour, per engine.

Failing to fund this reserve is probably the single biggest financial mistake an owner can make. It turns a predictable, manageable expense into a sudden, catastrophic bill that can ground your aircraft indefinitely.

Do Newer Planes Have Lower Maintenance Costs?

They do, but it's not quite that simple. A brand-new aircraft comes with a full factory warranty, which is fantastic. It covers most issues for the first few years, dramatically cutting your out-of-pocket repair costs. Newer designs and more efficient engines also mean your hourly (variable) costs are lower.

The catch? What you save in maintenance you often pay for in other areas. The aircraft's high value means much higher insurance premiums, and you'll be taking the biggest hit from depreciation in those first few years. An older, well-maintained aircraft might have more maintenance pop up, but its lower purchase price and insurance costs can easily balance the scales.

At Wexford Insurance Solutions, we specialize in providing clear, comprehensive insurance coverage that protects your high-value assets. Our experts understand the unique risks of aircraft ownership and can build a policy that gives you peace of mind in the air and on the ground. Secure your investment by visiting us at https://www.wexfordis.com.

Your Ultimate 2025 Home Maintenance Checklist: 10 Key Tasks

Your Ultimate 2025 Home Maintenance Checklist: 10 Key Tasks How to File a Property Damage Claim The Right Way

How to File a Property Damage Claim The Right Way